Product details

Hastelloy tube is a kind of nickel-based corrosion resistant alloy, mainly divided into nickel-chromium alloy and nickel-chromium molybdenum alloy two categories, with excellent comprehensive mechanical properties and better corrosion resistance. It is widely used in aviation and chemical fields.

Hastelloy tube is made of Hastelloy material cross-section is round, hexagonal, octagonal and other shapes of the bar material can be processed into bolts, nuts, gaskets, flanges, elbows and other products, while it uses chromium molybdenum as the main alloying element, designed to improve the adaptability to various media and temperature, and for different industry applications have been specially optimized. At the same time, Hastelloy rod also has good processing and welding performance, which is convenient for on-site maintenance.

|

Outer Diameter

|

6-2500mm, (3/8"-100")

|

|

Thickness

|

0.3-150mm,(SCH10-XXS)

|

|

Length:

|

2000mm, 2500mm, 3000mm, 5800mm,6000mm,12000mm,etc

|

|

Standard:

|

ASTM,JIS, AISI, GB, DIN, EN

|

|

Certification:

|

ISO, SGS

|

|

DIN/EN

|

2.4819、2.461、2.4602、2.4675、2.4665、2.4617、2.466

|

|

UNS No

|

N10276、N06455、N06022、N06200、N06002、N10665、N10675、N06030、N06035

|

|

Generic term

|

Hastelloy C-276、Hastelloy C-4、Hastelloy C-22、Hastelloy C-2000、Hastelloy X、Hastelloy B-2、Hastelloy B-3、Hastelloy G-30、Hastelloy G-35

|

|

Composition

|

57Ni-16Mo-16Cr-5Fe-4W-2.5Co-1Mn-0.35V-0.08Si-0.01C65Ni-16Cr-16Mo-0.7Ti-3Fe-2Co-1Mn-0.08Si-0.01C56Ni-22Cr-13Mo-3Fe-2.5Co-0.5Mn-0.35V-0.08Si-0.01C59Ni-23Cr-16Mo-1.6Cu-0.08Si-0.01C47Ni-22Cr-18Fe-9Mo-1.5Co-0.6W-0.1C-1mn-1Si-0.008B69Ni-28Mo-0.5Cr-1.8Fe-3W-1.0Co-1.0Mn-0.01C65Ni-28.5Mo-1.5Cr-1.5Fe-3W-3Co-3Mn-0.01C43Ni-30Cr-15Fe-5.5Mo-2.5W-5Co-2Cu-1.5Mn-0.03C58Ni-33Cr-8Mo-2Fe-0.6Si-0.3Cu-0.03C

|

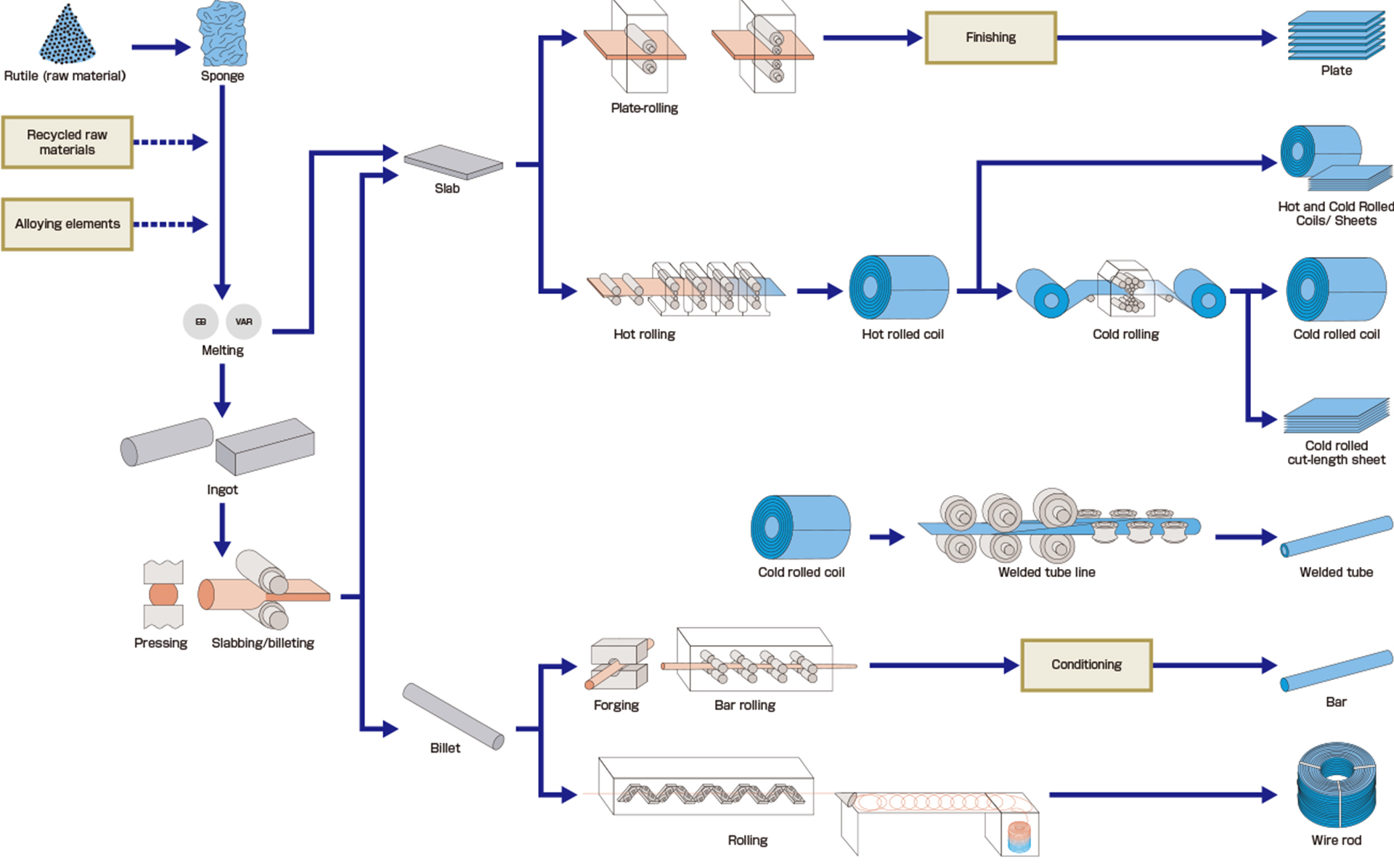

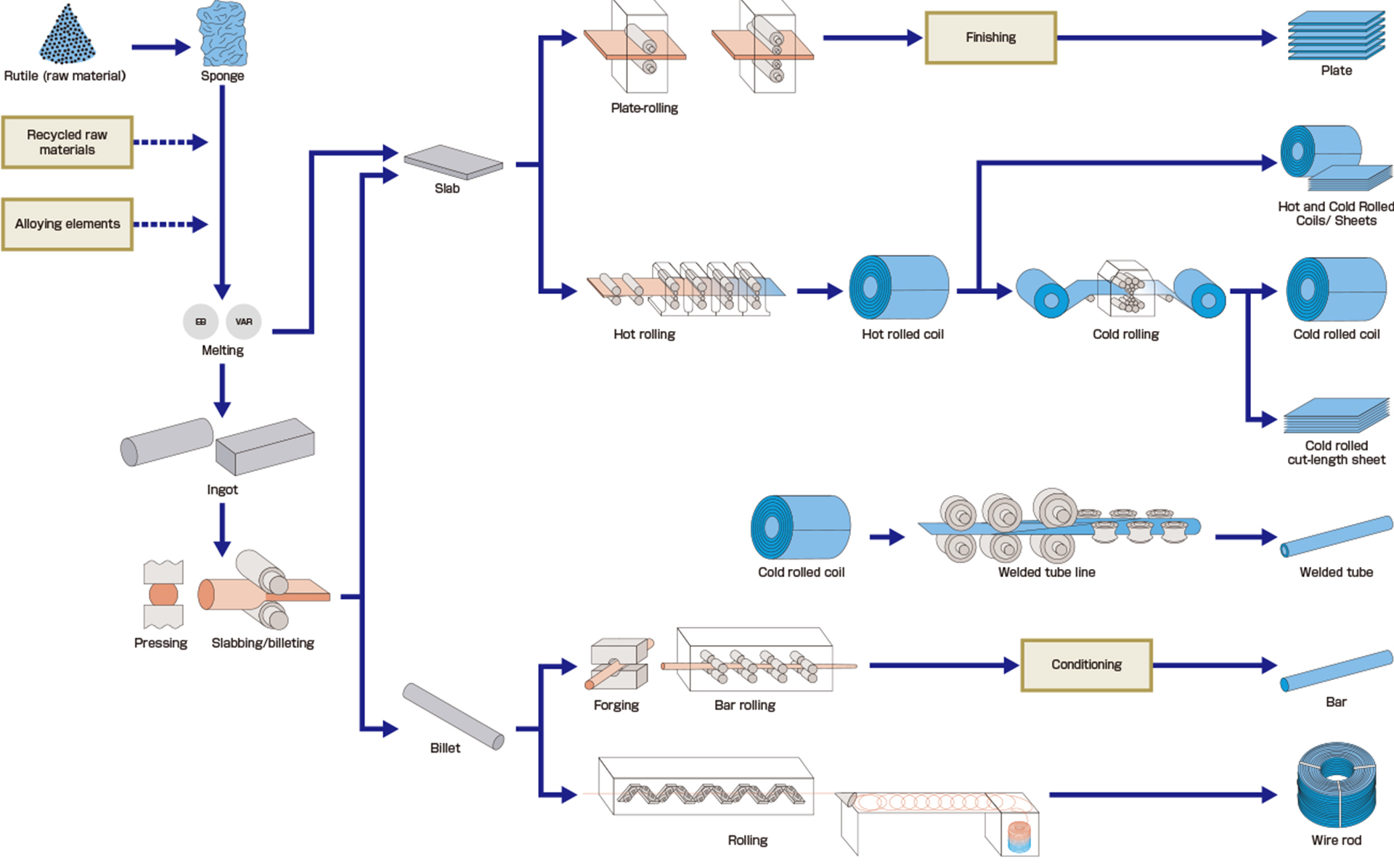

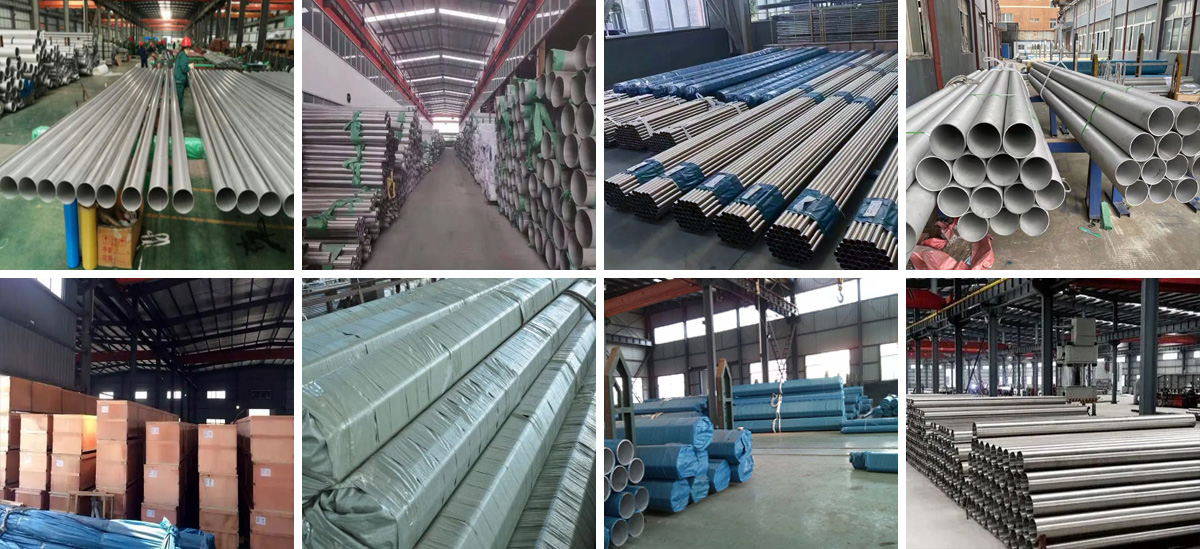

Product production process

We have advanced production lines and operating equipment, all products in the production of strict quality control to ensure that all products will not appear quality problems. All our products can also accept the professional quality inspection of third-party testing institutions and can issue relevant quality certificates.

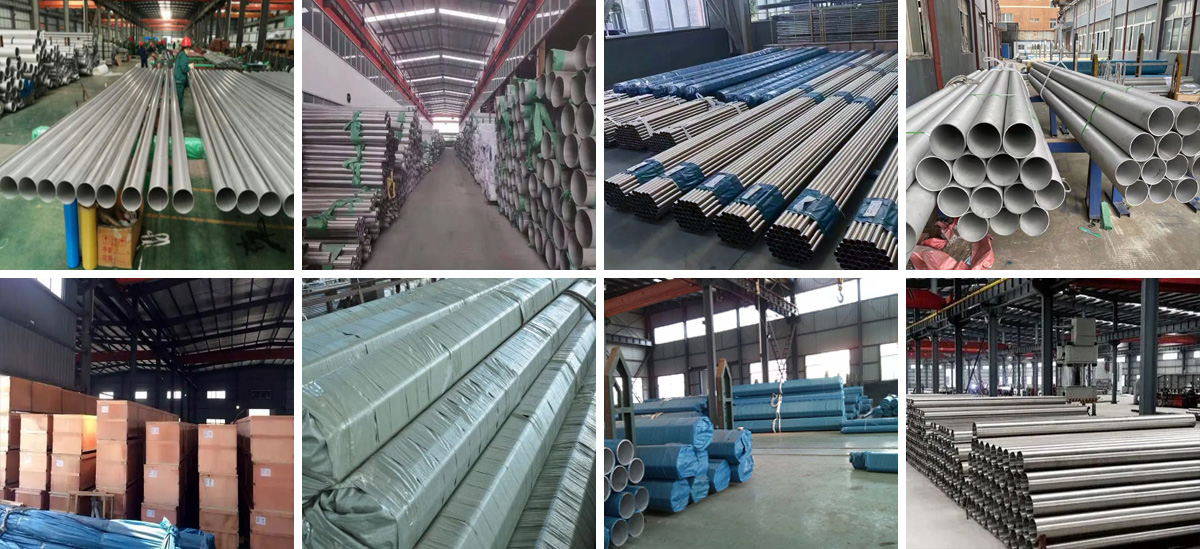

Product packaging and transportation

Customers can default to our packaging method can also be specified, we can give you professional advice according to your location to choose the appropriate packaging and transportation method, of course, you can also specify.

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties.

Alloy steels are broken down into two groups: low alloy steels and high alloy steels. The difference between the two is disputed. Smith and Hashemi define the difference at 4.0%, while Degarmo, et al., define it at 8.0%. Most commonly, the phrase "alloy steel" refers to low-alloy steels.

Strictly speaking, every steel is an alloy, but not all steels are called "alloy steels". The simplest steels are iron (Fe) alloyed with carbon (C) (about 0.1% to 1%, depending on type) and nothing else (excepting negligible traces via slight impurities); these are called carbon steels. However, the term "alloy steel" is the standard term referring to steels with other alloying elements added deliberately in addition to the carbon. Common alloyants include manganese (Mn) (the most common one), nickel (Ni), chromium (Cr), molybdenum (Mo), vanadium (V), silicon (Si), and boron (B). Less common alloyants include aluminium (Al), cobalt (Co), copper (Cu), cerium (Ce), niobium (Nb), titanium (Ti), tungsten (W), tin (Sn), zinc (Zn), lead (Pb), and zirconium (Zr).

The following is a range of improved properties in alloy steels (as compared to carbon steels): strength, hardness, toughness, wear resistance, corrosion resistance, hardenability, and hot hardness. To achieve some of these improved properties the metal may require heat treating.

Although alloy steels have been made for centuries, their metallurgy was not well understood until the advancing chemical science of the nineteenth century revealed their compositions. Alloy steels from earlier times were expensive luxuries made on the model of "secret recipes" and forged into such tools as knives and swords. Modern alloy steels of the machine age were developed as improved tool steels and as newly available stainless steels. Today alloy steels find uses in a wide array of applications, from everyday hand tools and flatware to highly demanding applications such as in the turbine blades of jet engines and in nuclear reactors.

JIMI STEEL MILL CO.,LTD, (“JIMI Steel” for short) is an international company integrating production, processing and sales. Always stand from the customer's perspective and provide customers with one-stop steel procurement services.

Headquartered in Dezhou the company has successively invested and built production lines of galvanized steel, color coating steel, seamless steel pipe, cold-rolled sheet and stainless steel products in China; Meanwhile, it has established long-term and friendly relations with Baosteel, Tisco, Posco and other major domestic and international steel mills to conveniently and efficiently provide customers with high-quality products and services. In addition, the company has also set up its own warehouses in major domestic ports to ensure that the goods are delivered to customers at the first time.

As long as you need steel, JIMI Steel will give you the best support!

Manufacturing capacity

Our production line is running well, the product stock is sufficient, and we also maintain close cooperation with major domestic and foreign steel mills to ensure timely delivery of goods for customers

Logistics tracking

After receiving the order, we will quickly prepare the goods for you and send them out, and track the logistics throughout the process to ensure that the goods are safely and quickly delivered to the customer's designated location

Quality assurance

All our products are produced with high-quality raw materials, and all products can accept professional quality inspection by third-party testing institutions and can issue relevant quality certificates

Worry free after sale

After placing the order, we will have a special after-sales manager to docking you, to help you solve any problems that may occur in the use of the process, if necessary, we can assist you to return or exchange goods

Name: Jimmy

Tel: +86-15753107623

E-mail: admin@jimi-steel.com

WeChat: 008615753107623

Whatsapp: 008615753107623

Add: No.19 West Street, Guangtai Mall, Xinhu Street, Decheng District, Dezhou City, China

Frequently Asked Questions(FAQ)

Have you encountered any problems? Here are some of our most frequently asked questions and answers. If there is nothing you would like to see, please contact us

How do I order your steel?

To order our steel, you need to visit our website and then contact our sales team to provide you with the material, model, payment method and terms you want.

How long after the order?

Under normal circumstances, if we have it in stock, we will start delivery within 7-14 days. In other cases that need to be customized, we will communicate with you specifically about the time limit. After the production is completed, we will deliver the car to you according to the mode of transportation you choose.

Do you offer custom products?

Yes, we offer custom service. Can be based on your needs and conditions.

Do you offer a return service if I need to return a product?

Yes, if you need to return a product, we offer a return service. Please note that returns are subject to our return policy, please consult your contact's dedicated account manager for details.

How about the quality of your products? Is there a guarantee?

All our products are subject to strict quality testing and come with a quality guarantee.

Do you provide after-sales service?

Yes, after you place an order, we will have a dedicated account manager online 24 hours to solve some problems you may have in use.

JIMI STEEL MILL LIMITED

JIMI STEEL MILL LIMITED