Product details

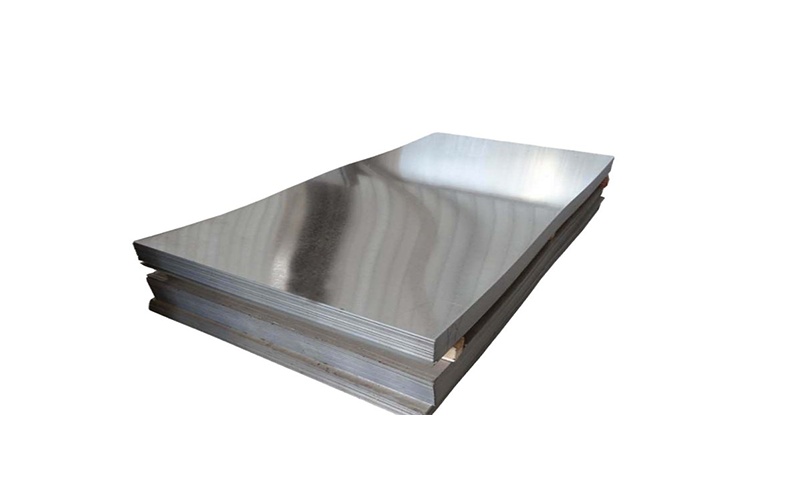

The G550 aluminized zinc plate is a plate made of alloying elements such as aluminum, zinc and silicon, which is usually enhanced by a galvanizing process to enhance its corrosion resistance. The material has a strong structure and high tensile strength, which can withstand greater external impact. It also has the characteristics of high temperature, weather and corrosion resistance, and can maintain its original state for a long time under harsh environmental conditions.

The G550 aluminum-plated zinc plate has good machining performance and can be bent, cut and pressed according to the needs of the building. The material of the G550 aluminum-plated zinc plate gives it excellent strength and rigidity. It can be used for key parts such as load-bearing wall panels, beams, columns and floor panels in building structures. Compared to traditional building materials such as concrete and masonry, the G550 aluminum-plated zinc plate is lighter and still provides the same strength.

|

Product Name

|

Galvanized steel coil sheet

|

|

Width

|

1000mm/1219mm/1240mm/1500mm/2000mm oras customer's requirements

|

|

Thickness

|

Cold rolled:0.1~4.0mm Hot rolled:4mm~300mm

|

|

Length

|

100mm to 12000mm or as customer's request

|

|

Zinc coating

|

60g/m2-600g/m2

|

|

Standards

|

AISI ASTM JIS SUS DIN GBJISG33021998ASTMA653M/A924M 2004

|

|

Material

|

SGHC,SGCC,DX51D,Q195,all according to the customers request

|

|

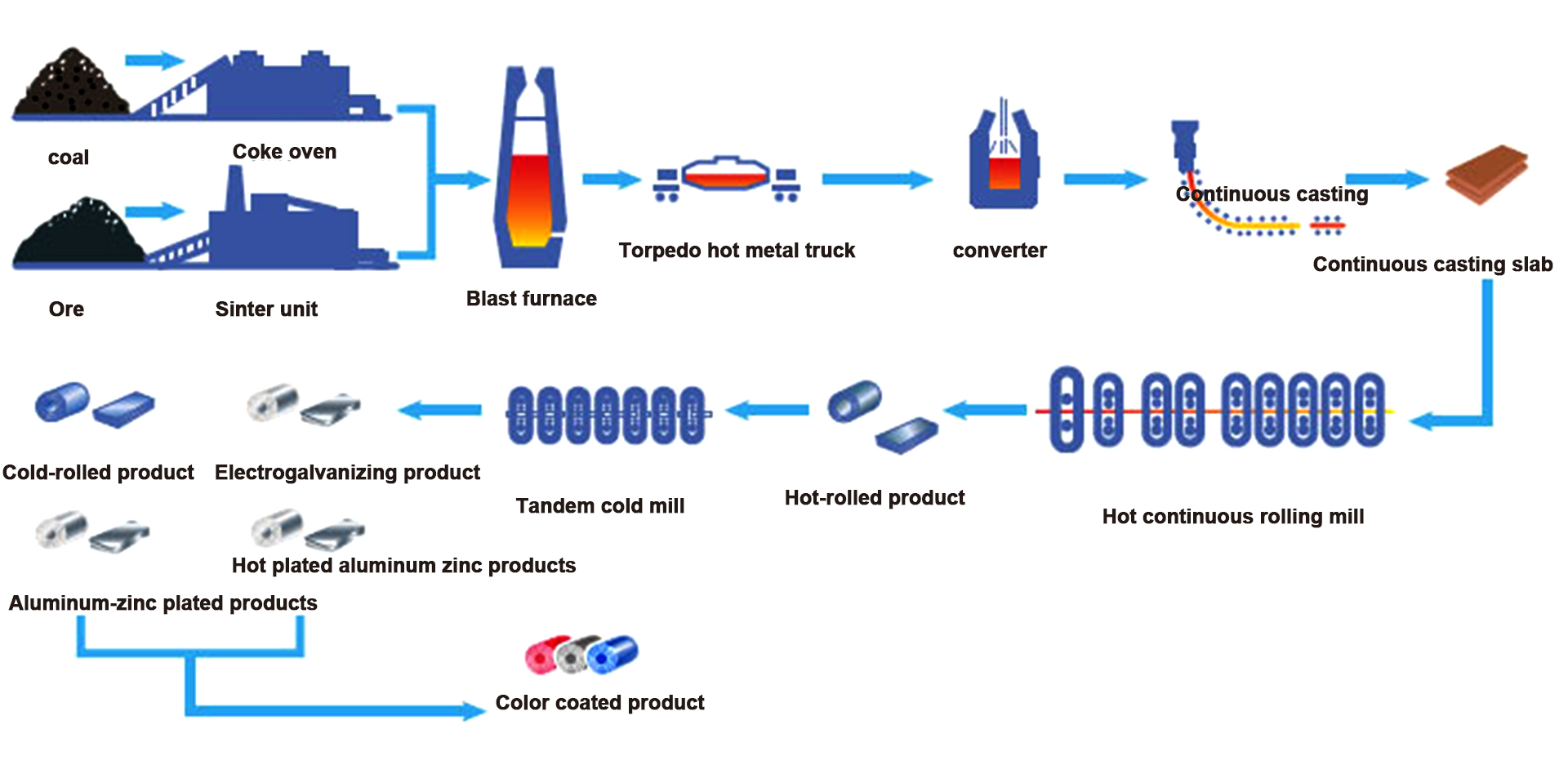

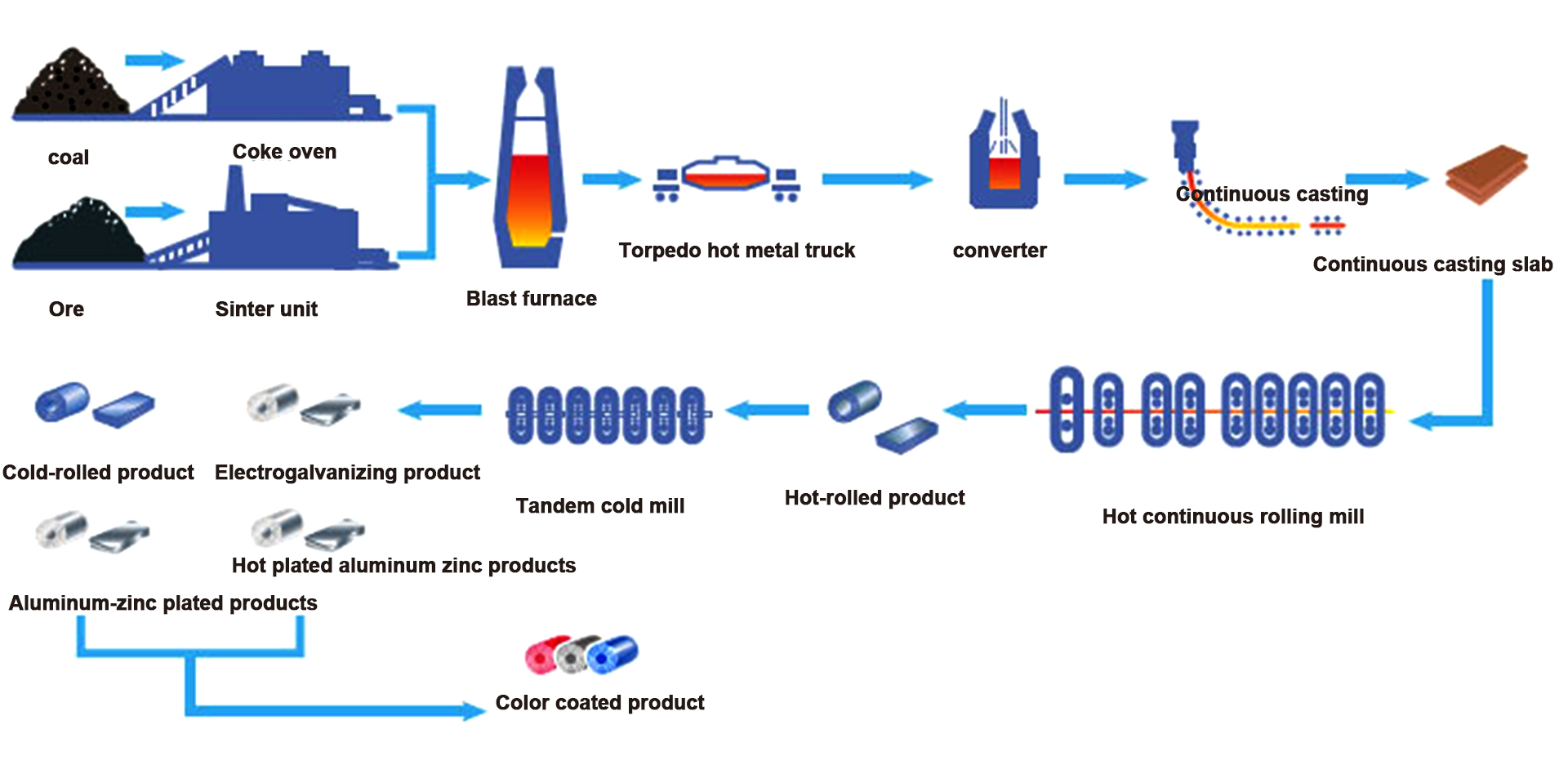

Production process

|

Cold rolled steel coil-uncoil-Pickling-Annealed-hot dipped galvanizing-cooling -surface treatment -rolling

|

|

Coating Weight

|

30-275a/m2,double side

|

|

Spangle

|

Big spanglenormalspangle,small spangle,non-spangle

|

|

Edge

|

mill edge,cut edge

|

|

Surface treatment

|

Passivation or ChromatedSkin PassOil or Unoiledor Antifinger print

|

|

Coil weight

|

3-8MT/Coil or as your request

|

Product production process

We have advanced production lines and operating equipment, all products in the production of strict quality control to ensure that all products will not appear quality problems. All our products can also accept the professional quality inspection of third-party testing institutions and can issue relevant quality certificates.

Product packaging and transportation

Customers can default to our packaging method can also be specified, we can give you professional advice according to your location to choose the appropriate packaging and transportation method, of course, you can also specify.

Galvanizing refers to a rust-proof method of laying metallic zinc on the surface of iron or steel. Zinc is a metal with high corrosion resistance. It can insulate iron from oxygen and water, so that iron cannot undergo the chemical reactions required for rusting. Because zinc is more mobile than iron, even if the zinc plated appears Even if damaged, zinc can still prevent rust by electrochemical means of sacrificial protection. The main galvanizing methods include hot dip galvanizing (HDG), electro galvanizing (EG) and cold galvanizing.

Galvalume is a metallic material that is an alloy of zinc and aluminum coated on the surface of steel and is commonly used in the construction and manufacturing industries. Compared with ordinary galvanized steel sheets, galvanized materials have better corrosion resistance, longer service life, more beautiful appearance, and long service life. Therefore, it is a widely used material.

Color coating usually refers to a brightly colored, colorful and diverse coating, which is mainly composed of water-based resin, pigments and additives.

The purpose of color coating is to add baking coating technology to the surface of galvanized coils, galvalume coils or cold-rolled coils to apply paint on the surface.

The advantages of color picture boards are as follows:

Strong weather resistance: able to withstand damage caused by extreme weather, such as acid rain, ultraviolet rays, high temperatures, etc.

Good corrosion resistance: It can effectively prevent metal plates from being polluted and corroded, and extend their service life.

High aesthetics: It has a variety of colors and textures to choose from, which increases the decoration and aesthetics of the building.

Construction is convenient and fast: the color steel plates are made in the factory and installed at the factory, which is easy for factory planning, production and standardization, and reduces construction costs.

The main functions of steel roofing:

1. Prevent the influence of natural wind, snow, rain, solar radiation and low temperature in winter, so that the space under the roof has a good use environment. Therefore, steel structure roofs should meet requirements such as waterproofing, thermal insulation, heat insulation, sound insulation, and fire protection in structural design.

2. Bear the wind load, snow load and self-weight of the roof on the roof, and also provide horizontal support to the upper part of the house. Therefore, it is required that when designing the roof structure, the bearing capacity, stiffness and overall spatial stability of the roof components should be ensured.

What is the cost of a steel roof? This is closely related to a variety of factors, such as the quality of the project materials, the scale of the project, the difficulty of the project, etc., which all affect the price changes, so the cost of the steel structure roof cannot be To sum up, the best way is to give the most reasonable quotation budget based on the on-site construction conditions.

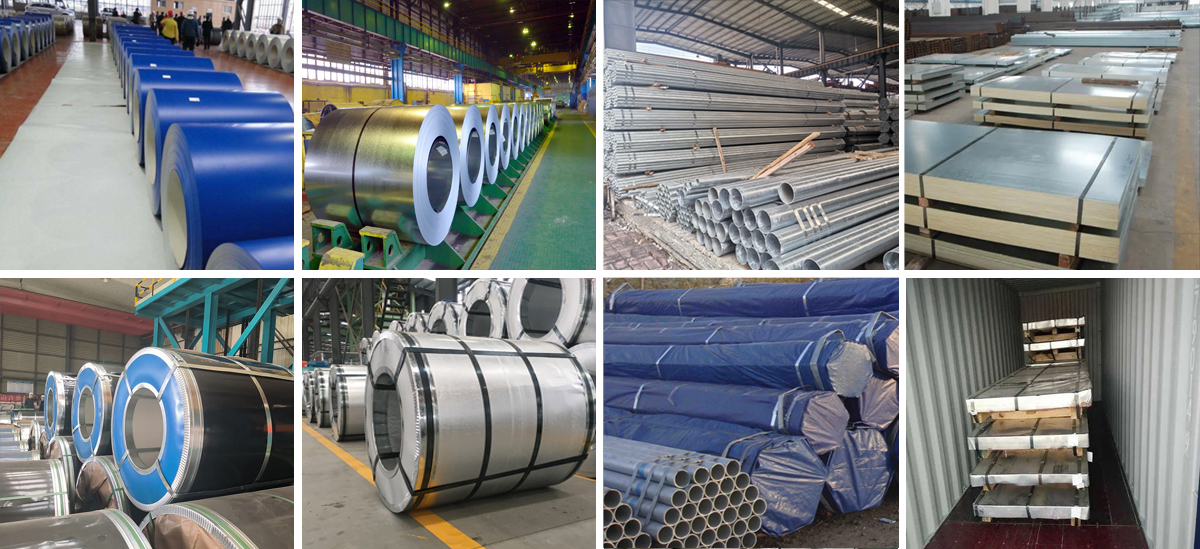

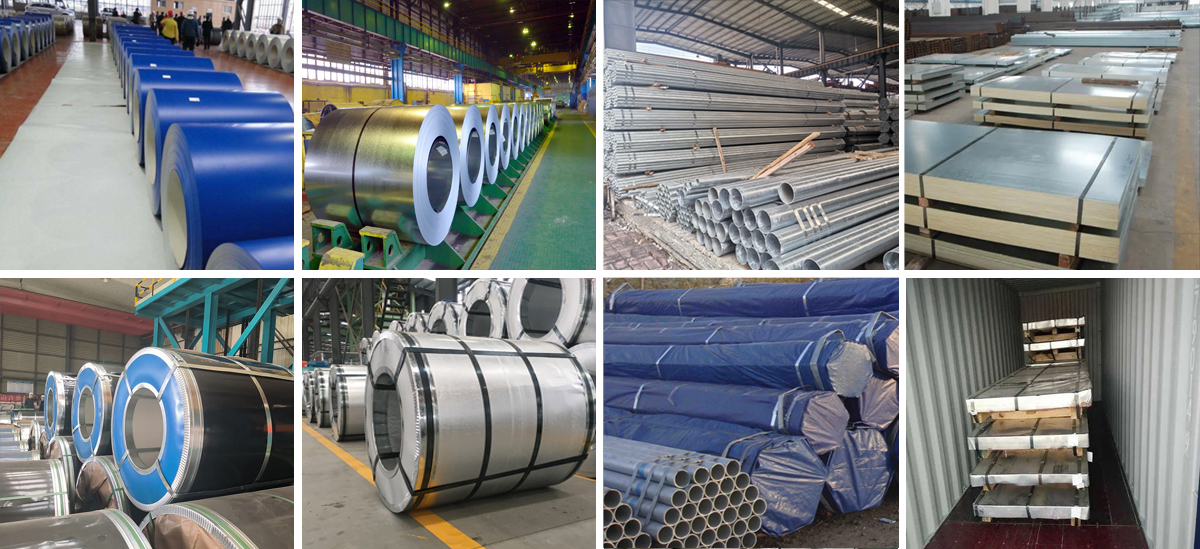

JIMI STEEL MILL CO.,LTD, (“JIMI Steel” for short) is an international company integrating production, processing and sales. Always stand from the customer's perspective and provide customers with one-stop steel procurement services.

Headquartered in Dezhou the company has successively invested and built production lines of galvanized steel, color coating steel, seamless steel pipe, cold-rolled sheet and stainless steel products in China; Meanwhile, it has established long-term and friendly relations with Baosteel, Tisco, Posco and other major domestic and international steel mills to conveniently and efficiently provide customers with high-quality products and services. In addition, the company has also set up its own warehouses in major domestic ports to ensure that the goods are delivered to customers at the first time.

As long as you need steel, JIMI Steel will give you the best support!

Manufacturing capacity

Our production line is running well, the product stock is sufficient, and we also maintain close cooperation with major domestic and foreign steel mills to ensure timely delivery of goods for customers

Logistics tracking

After receiving the order, we will quickly prepare the goods for you and send them out, and track the logistics throughout the process to ensure that the goods are safely and quickly delivered to the customer's designated location

Quality assurance

All our products are produced with high-quality raw materials, and all products can accept professional quality inspection by third-party testing institutions and can issue relevant quality certificates

Worry free after sale

After placing the order, we will have a special after-sales manager to docking you, to help you solve any problems that may occur in the use of the process, if necessary, we can assist you to return or exchange goods

Name: Jimmy

Tel: +86-15753107623

E-mail: admin@jimi-steel.com

WeChat: 008615753107623

Whatsapp: 008615753107623

Add: No.19 West Street, Guangtai Mall, Xinhu Street, Decheng District, Dezhou City, China

Frequently Asked Questions(FAQ)

Have you encountered any problems? Here are some of our most frequently asked questions and answers. If there is nothing you would like to see, please contact us

How do I order your steel?

To order our steel, you need to visit our website and then contact our sales team to provide you with the material, model, payment method and terms you want.

How long after the order?

Under normal circumstances, if we have it in stock, we will start delivery within 7-14 days. In other cases that need to be customized, we will communicate with you specifically about the time limit. After the production is completed, we will deliver the car to you according to the mode of transportation you choose.

Do you offer custom products?

Yes, we offer custom service. Can be based on your needs and conditions.

Do you offer a return service if I need to return a product?

Yes, if you need to return a product, we offer a return service. Please note that returns are subject to our return policy, please consult your contact's dedicated account manager for details.

How about the quality of your products? Is there a guarantee?

All our products are subject to strict quality testing and come with a quality guarantee.

Do you provide after-sales service?

Yes, after you place an order, we will have a dedicated account manager online 24 hours to solve some problems you may have in use.

JIMI STEEL MILL LIMITED

JIMI STEEL MILL LIMITED