Product details

Carbon steel square pipe is a kind of carbon steel pipe with square cross-section shape.

Carbon steel square pipe is made of high-quality carbon steel, has good mechanical properties and strength, and toughness and corrosion resistance. Its characteristics are as follows:

High strength: Carbon steel square tubes are made of strong carbon steel with excellent mechanical properties and strong compression resistance.

Corrosion resistance: After special treatment, carbon steel square pipe has strong corrosion resistance.

Easy to process: carbon steel square pipe is easy to cut, drill and weld and other processing operations.

|

Thickness

|

1-200mm;or as required

|

Length:

|

2000-16000mm,or as required

|

|

Dimensions

|

10*20-600*800(mm)

|

Technique

|

Hot Rolled Or Cold Rolle

|

|

Heat Treatment

|

Annealed; Quenched; Tempered

|

Surface treatment

|

Rust remove, black painting,Galvanized, antirust oil, varnish, 3PE,

|

|

Certification:

|

CE, ISO, SGS,BV,Mill Certificate

|

Standard:

|

ASTM,JIS,GB,DIN,EN

|

|

price terms

|

FOB,CRF,CIF,EXW, CPT

|

Payment Terms

|

T/T, L/C at sight,West Union

|

|

Grade

|

Q195—Grade B, SS330, SPC, S185

|

|

Q215—Grade C,CS Type B, SS330, SPHC,

|

|

Q235---Grade D, SS400, S235JR, S235JO, S235J2,

|

|

Q345---SS500, ST52,S355JR

|

|

Delivery Detail

|

Standard has Stock; Normal About 3-5days; Custom-made 15-20days;According to order's quantity.

|

|

Packing

|

standard export packing (inside:water proof paper,outside:fumigated wooden box)

|

|

Hexagon Shape Bundle, Covered With Tarpaulin, Containers Or In Bulk

|

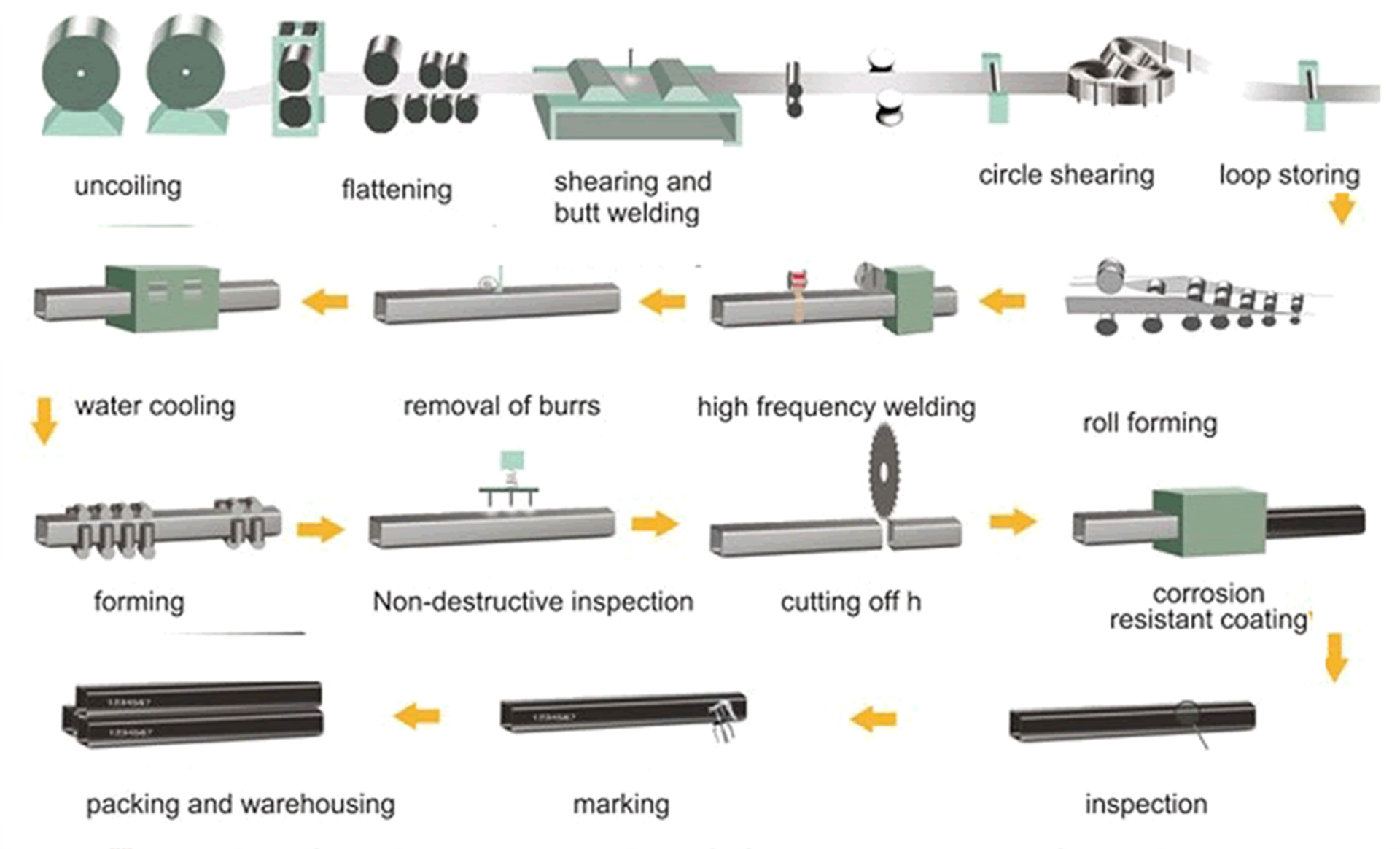

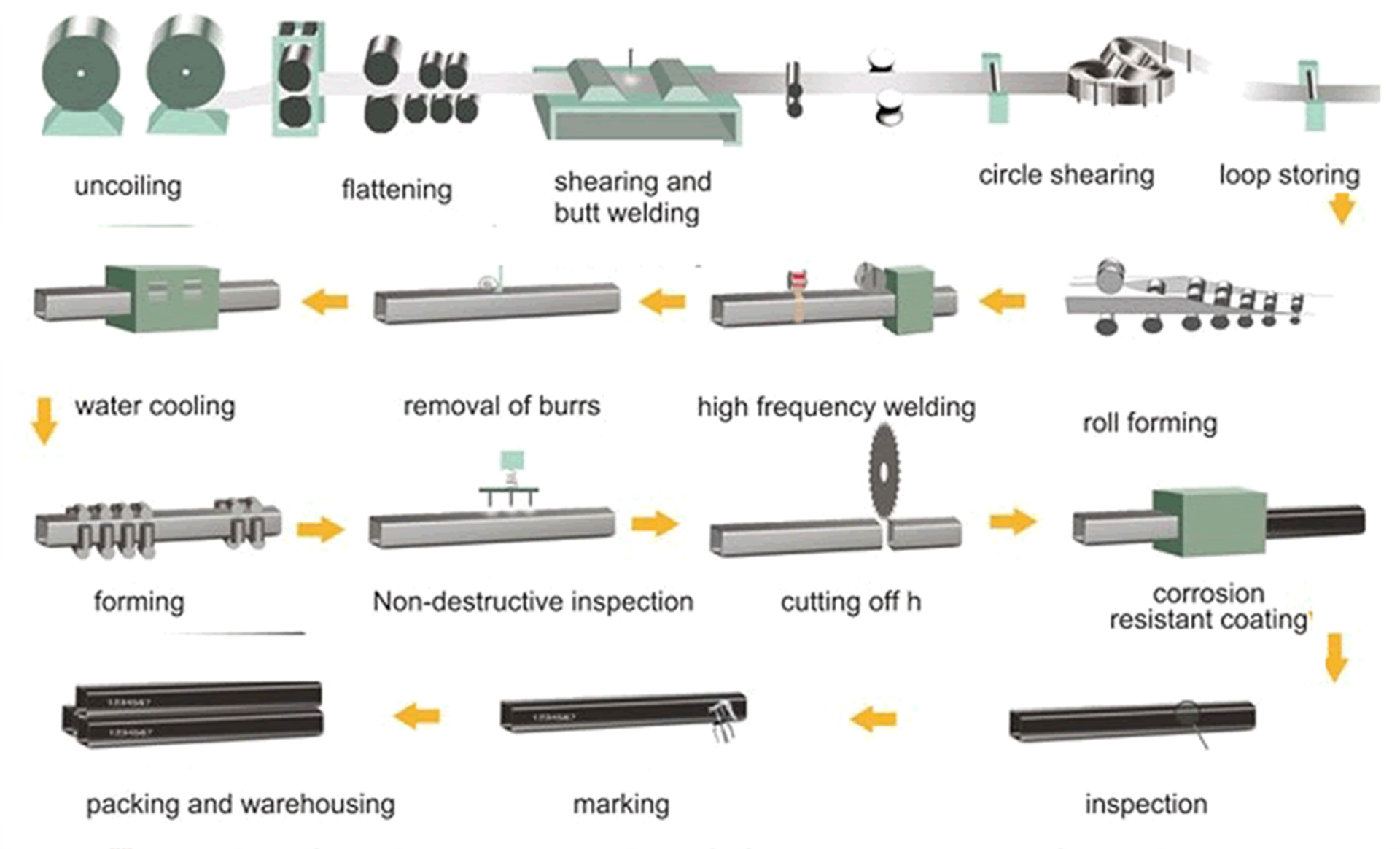

Product production process

We have advanced production lines and operating equipment, all products in the production of strict quality control to ensure that all products will not appear quality problems. All our products can also accept the professional quality inspection of third-party testing institutions and can issue relevant quality certificates.

Product packaging and transportation

Customers can default to our packaging method can also be specified, we can give you professional advice according to your location to choose the appropriate packaging and transportation method, of course, you can also specify.

Low-carbon Steel

Low-carbon steel, commonly known as mild steel, is by far the most common type of steel. Because of its low cost and material properties, low-carbon steel is suitable for a wide range of applications. Low-carbon steel contains approximately 0.05-0.25% carbon, making it malleable and ductile. Mild steel has a low tensile strength, but it is inexpensive and straightforward to form; carburizing can increase surface hardness.

High-strength, low-alloy steels (HSLA) are also categorized as low-carbon steels, with other ingredients including copper, nickel, vanadium, and molybdenum. Together, these can account for up to 10% of the steel composition. As the name implies, high-strength, low-alloy steels have higher strengths due to heat treatment. They also retain ductility, allowing them to be readily formed and machined. HSLA is more corrosion-resistant than regular low-carbon steel.

Medium-carbon Steel

Medium-carbon steel has 0.30 – 0.50% carbon and 0.60 – 1.65% manganese. This steel’s mechanical properties can be enhanced by a heat treatment involving austenitizing, followed by quenching and tempering, giving them a martensitic microstructure.

Heat treatment is only possible on extremely thin portions. However, steel can add additional alloying elements such as chromium, molybdenum, and nickel to increase its capacity to be heat treated and thus hardened.

Hardened medium-carbon steels have greater strength than low-carbon steels but at the sacrifice of ductility and toughness. This steel is mostly used in manufacturing machine components like shafts, axles, gears, crankshafts, couplings, and forgings. Still, it may also be used in rails and railway wheels.

High-carbon Steel

High-carbon steel has 0.60– 1.00% carbon and 0.30 – 0.90% manganese. It possesses the greatest hardness and toughness of carbon steel but the least ductility. Because they are nearly always hardened and tempered, high-carbon steels are extremely wear-resistant. High carbon steels might be employed in springs, rope wires, hammers, screwdrivers, and wrenches.

Tool steels and die steels are high-carbon steels containing extra alloying elements such as chromium, vanadium, molybdenum, and tungsten. The incorporation of these elements leads to particularly tough wear-resistant steel, which is a consequence of the production of carbide compounds like tungsten carbide (WC).

Properties And Applications of Common Carbon Steel Grades

Carbon steel comes in various forms, and can be used in many industries and sectors. Low-carbon steels are frequently used in vehicle body components, structural forms (I-beams, channel and angle iron), pipelines, building and bridge components, and food cans. Medium-carbon steels are frequently used for railway tracks, train wheels, crankshafts, and gears and machinery parts needing this combination of qualities because of their high strength, resistance to wear, and toughness. High-carbon steels are utilized in cutting tools, springs, great-strength wire, and dies due to their high wear resistance and hardness.

Low-carbon, medium-carbon, and high-carbon steel correspond to some common grades. The following table compares several carbon steel grades’ examples, qualities, and applications.

|

AISI/ASTM name

|

Carbon content (%)

|

Tensile strength (MPa)

|

Yield strength (MPa)

|

Ductility (% elongation in 50 mm)

|

Applications

|

|

1010

|

0.1

|

325

|

180

|

28

|

Automobile panels, nails, wire

|

|

1020

|

0.2

|

380

|

205

|

25

|

Pipes, structural steel, sheet steel

|

|

A36

|

0.29

|

400

|

220

|

23

|

Structural

|

|

A516 Grade 70

|

0.31

|

485

|

260

|

21

|

Low-temperature pressure vessels

|

|

1030

|

0.27 – 0.34

|

460

|

325

|

12

|

Machinery parts, gears, shifts, axles, bolts

|

|

1040

|

0.37 – 0.44

|

620

|

415

|

25

|

Crankshafts, couplings, cold headed parts.

|

|

1080

|

0.75 – 0.88

|

924

|

440

|

12

|

Music wire

|

|

1095

|

0.90 – 1.04

|

665

|

380

|

10

|

Springs, cutting tools

|

JIMI STEEL MILL CO.,LTD, (“JIMI Steel” for short) is an international company integrating production, processing and sales. Always stand from the customer's perspective and provide customers with one-stop steel procurement services.

Headquartered in Dezhou the company has successively invested and built production lines of galvanized steel, color coating steel, seamless steel pipe, cold-rolled sheet and stainless steel products in China; Meanwhile, it has established long-term and friendly relations with Baosteel, Tisco, Posco and other major domestic and international steel mills to conveniently and efficiently provide customers with high-quality products and services. In addition, the company has also set up its own warehouses in major domestic ports to ensure that the goods are delivered to customers at the first time.

As long as you need steel, JIMI Steel will give you the best support!

Manufacturing capacity

Our production line is running well, the product stock is sufficient, and we also maintain close cooperation with major domestic and foreign steel mills to ensure timely delivery of goods for customers

Logistics tracking

After receiving the order, we will quickly prepare the goods for you and send them out, and track the logistics throughout the process to ensure that the goods are safely and quickly delivered to the customer's designated location

Quality assurance

All our products are produced with high-quality raw materials, and all products can accept professional quality inspection by third-party testing institutions and can issue relevant quality certificates

Worry free after sale

After placing the order, we will have a special after-sales manager to docking you, to help you solve any problems that may occur in the use of the process, if necessary, we can assist you to return or exchange goods

JIMI STEEL MILL LIMITED

JIMI STEEL MILL LIMITED