Product details

1.4301 stainless steel bar is a high alloy steel, also known as 304 stainless steel. It contains chromium, nickel, molybdenum, titanium and other alloying elements, with excellent corrosion resistance, high strength, high toughness, good processing properties and welding properties and other characteristics. 1.4301 Stainless steel bar material is widely used in machinery, automotive, petroleum, chemical, pharmaceutical, food, environmental protection and other industries, can be used to manufacture a variety of high-strength, wet-resistant, corrosion-resistant equipment parts and pipeline accessories, such as valves, pumps, pipes, flanges and so on.

|

Type:

|

Stainless steel bar

|

|

Outer Diameter

|

4-600mm (3/8"-25")

|

|

Length:

|

40-400mm,2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm, etc

|

|

Standard:

|

ASTM,JIS, AISI, GB, DIN, EN

|

|

Surface:

|

BA,2B,NO.1,NO.4,4K,HL,8K

|

|

Application:

|

It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.

|

|

It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc.

|

|

Certification:

|

ISO, SGS,BV

|

|

Technique:

|

Forging and cold drawing

|

|

Edge:

|

Mill Edge Slit Edge

|

|

Quality:

|

SGS Inspection

|

|

Grade(ASTM UNS)

|

201,304,304L,321,316,316L,317L,347H,309S,310S,904L,

|

|

S32205,2507,254SMOS,32760,253MA,N08926

|

|

Grade(EN)

|

1.4301,1.4307,1.4541,1.4401,1.4404,1.4571,1.4438,1.4539,1.4547,

|

|

1.4529,1.4562,1.4410,1.4878,1.4845,1.4828,1.4876,2.4858,2.4819

|

|

Place of Origin:

|

Tianjin, China (Mainland)

|

|

Supply Ability:

|

5000 Ton/Tons per Month

|

|

Packaging Details

|

in bundle,plastic bags,thin film,wooden pallet,standard seaworthy export packing or as customer demands

|

|

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM

|

|

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM

|

|

40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM

|

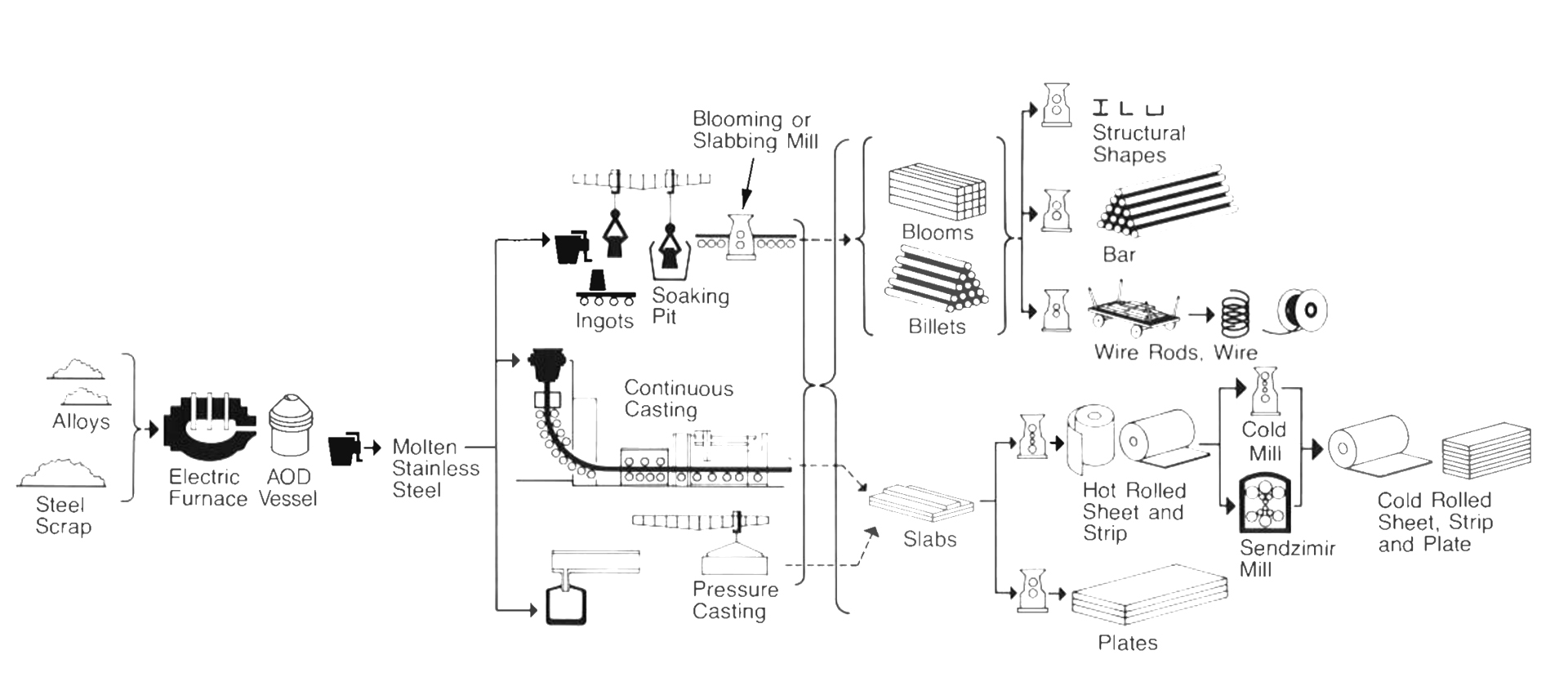

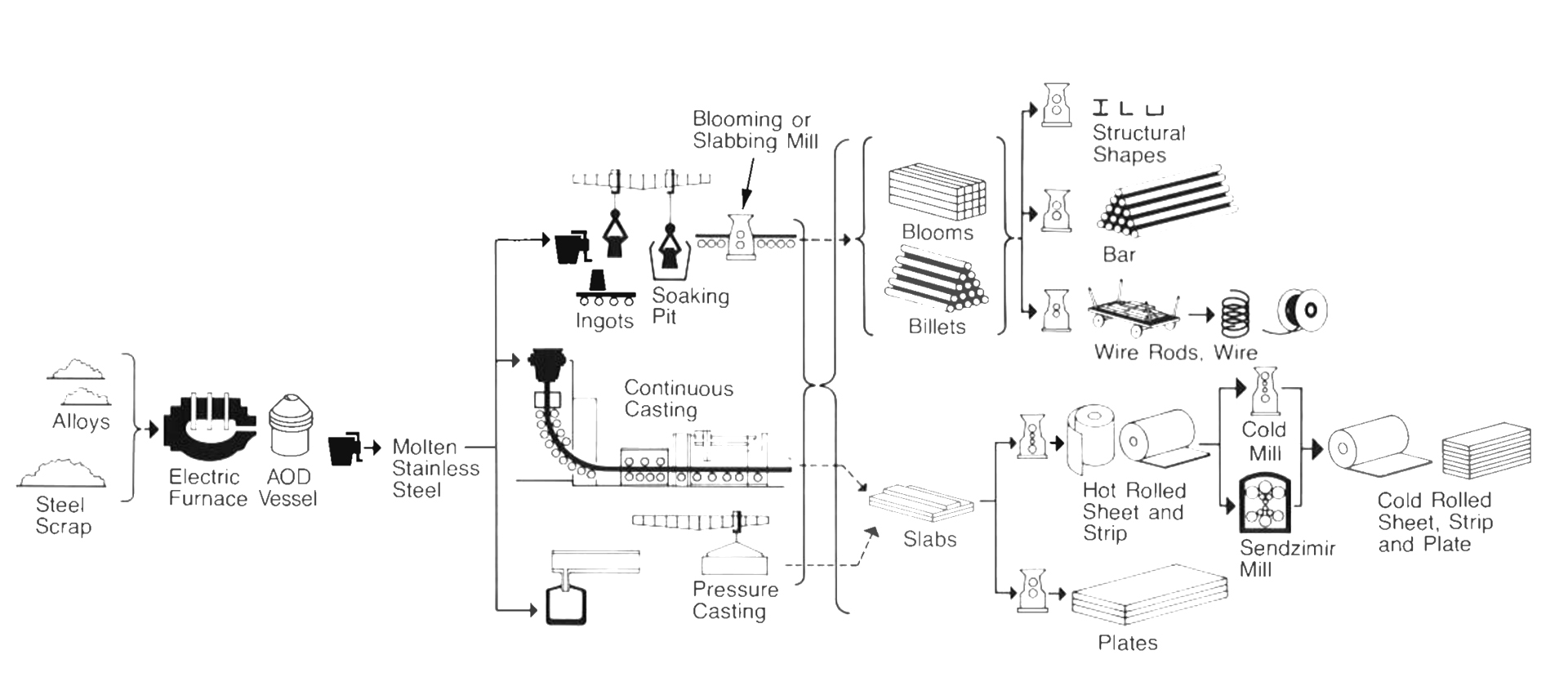

Product production process

We have advanced production lines and operating equipment, all products in the production of strict quality control to ensure that all products will not appear quality problems. All our products can also accept the professional quality inspection of third-party testing institutions and can issue relevant quality certificates.

Product packaging and transportation

Customers can default to our packaging method can also be specified, we can give you professional advice according to your location to choose the appropriate packaging and transportation method, of course, you can also specify.

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon and other nonmetals to obtain other desired properties. Stainless steel's resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.

The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products.

The biological cleanability of stainless steel is superior to both aluminium and copper, and comparable to glass. Its cleanability, strength, and corrosion resistance have prompted the use of stainless steel in pharmaceutical and food processing plants.

The density of stainless steel can be somewhere between 7,500kg/m3 to 8,000kg/m3 depending on the alloy.

|

Type

|

Cr

|

Ni

|

Cmax

|

Other Elements

|

Major Characteristics

|

|

303

|

17.00-19.00

|

8.00-10.00

|

0.15

|

S 0.15 min

|

† Free-machining modification of Type 302

|

|

303 Se

|

17.00-19.00

|

8.00-10.00

|

0.15

|

Se 0.15 min

|

† Free-machining version of Type 302. Produces better surface finish than Type 303.

|

|

304

|

18.00-20.00

|

8.00-10.00

|

0.08

|

–

|

† Low carbon variation of Type 302. Minimizes carbide precipitation during welding

|

|

304L

|

18.00-20.00

|

8.00-10.00

|

0.03

|

–

|

† Extra-low carbon content eliminates harmful carbide precipitation due to welding

|

|

309

|

22.00-24.00

|

12.00-15.00

|

0.20

|

–

|

† High strength and resistance to scaling at high temperatures

|

|

310

|

24.00-26.00

|

19.00-22.00

|

0.20

|

–

|

† Higher alloy content improves basic characteristics of Type 309

|

|

316

|

16.00-18.00

|

10.00-14.00

|

0.08

|

Mo 2.00-3.00

|

† Mo improves general corrosion and pitting resistance and high temperature strength over that of Type 302

|

|

316L

|

16.00-18.00

|

10.00-14.00

|

0.20

|

Mo 2.00-3.00

|

† Extra-low carbon version of Type 316. Eliminates harmful carbide precipitation due to welding

|

|

317

|

18.00-20.00

|

11.00-15.00

|

0.08

|

Mo 3.00-4.00

|

† Higher alloy content improves basic advantages of Type 316

|

|

321

|

17.00-19.00

|

9.00-12.00

|

0.08

|

Ti 5 x C. min

|

† Stabilized to permit use in 800-1500°F temperature range without harmful carbide precipitation

|

|

347

|

17.00-19.00

|

9.00-13.00

|

.008

|

Cb + Ta 10 x C. min

|

† Characteristics similar to Type 321. Stabilized by Cb and Ta.

|

|

348

|

17.00-19.00

|

9.00-13.00

|

0.08

|

Ta 0.10 max Cb 0.20 max

Cb + Ta 10 x C min

|

† Similar to Type 347 but Ta reduced for atomic energy applications

|

|

410

|

11.50-13.50

|

-

|

0.15

|

-

|

¥ Lowest cost general purpose stainless steel. Wide use where corrosion is not severe.

|

|

416

|

12.00-14.00

|

-

|

0.15

|

S 0.15 min

|

¥ Free-machining version of Type 410.

|

|

420

|

12.00-14.00

|

-

|

0.15 min

|

-

|

¥ Similar variation of Type 410 but higher carbon produces higher strength and hardness.

|

|

430

|

14.00-18.00

|

-

|

0.12

|

-

|

* Most popular of the chromium types. Combines good corrosion and heat resistance and mechanical properties.

|

|

430 F

|

14.00-18.00

|

-

|

0.12

|

S 0.15 min

|

* Free-machining version of Type 430.

|

440A

440B

440C

|

16.00-18.00

16.00-18.00

16.00-18.00

|

-

|

0.60-0.75

0.75-0.95

0.95-1.20

|

-

|

¥ Series of high carbon types. Some basic composition with varying carbon content. Higher carbon produces higher strength and hardness but lower toughness. All Type 440 versions are corrosion resistant only in the hardened condition.

|

|

446

|

23.00-27.00

|

-

|

0.20

|

-

|

* Similar to Type 442 but Cr increased to provide maximum resistance to scaling.

|

|

15-5 PH

|

14.00-15.50

|

3.50-5.50

|

0.07

|

Cu 2.50-4.50

|

• Similar in properties and characteristics to 17-4 PH but has superior transverse ductility and toughness.

|

|

PH 15-7 Mo

|

14.00-16.00

|

6.50-7.75

|

0.09

|

Mo 2.00-3.00

Al 0.75-1.50

|

•• Special type similar to 17-7 PH but with higher strength.

|

|

17-4 PH

|

15.50-17.50

|

3.00-5.00

|

0.07

|

Cu 3.00-5.00

|

• Special type that combines excellent corrosion resistance…high strength and hardness… low temperature hardening and good fabrication characteristics.

|

|

17-7 PH

|

16.00-18.00

|

6.50-7.75

|

0.09

|

AL 0.75-1.25

|

•• Special ultra-high strength type with good formability and excellent fabricating characteristics.

|

JIMI STEEL MILL CO.,LTD, (“JIMI Steel” for short) is an international company integrating production, processing and sales. Always stand from the customer's perspective and provide customers with one-stop steel procurement services.

Headquartered in Dezhou the company has successively invested and built production lines of galvanized steel, color coating steel, seamless steel pipe, cold-rolled sheet and stainless steel products in China; Meanwhile, it has established long-term and friendly relations with Baosteel, Tisco, Posco and other major domestic and international steel mills to conveniently and efficiently provide customers with high-quality products and services. In addition, the company has also set up its own warehouses in major domestic ports to ensure that the goods are delivered to customers at the first time.

As long as you need steel, JIMI Steel will give you the best support!

Manufacturing capacity

Our production line is running well, the product stock is sufficient, and we also maintain close cooperation with major domestic and foreign steel mills to ensure timely delivery of goods for customers

Logistics tracking

After receiving the order, we will quickly prepare the goods for you and send them out, and track the logistics throughout the process to ensure that the goods are safely and quickly delivered to the customer's designated location

Quality assurance

All our products are produced with high-quality raw materials, and all products can accept professional quality inspection by third-party testing institutions and can issue relevant quality certificates

Worry free after sale

After placing the order, we will have a special after-sales manager to docking you, to help you solve any problems that may occur in the use of the process, if necessary, we can assist you to return or exchange goods

Name: Jimmy

Tel: +86-15753107623

E-mail: admin@jimi-steel.com

WeChat: 008615753107623

Whatsapp: 008615753107623

Add: No.19 West Street, Guangtai Mall, Xinhu Street, Decheng District, Dezhou City, China

Frequently Asked Questions(FAQ)

Have you encountered any problems? Here are some of our most frequently asked questions and answers. If there is nothing you would like to see, please contact us

How do I order your steel?

To order our steel, you need to visit our website and then contact our sales team to provide you with the material, model, payment method and terms you want.

How long after the order?

Under normal circumstances, if we have it in stock, we will start delivery within 7-14 days. In other cases that need to be customized, we will communicate with you specifically about the time limit. After the production is completed, we will deliver the car to you according to the mode of transportation you choose.

Do you offer custom products?

Yes, we offer custom service. Can be based on your needs and conditions.

Do you offer a return service if I need to return a product?

Yes, if you need to return a product, we offer a return service. Please note that returns are subject to our return policy, please consult your contact's dedicated account manager for details.

How about the quality of your products? Is there a guarantee?

All our products are subject to strict quality testing and come with a quality guarantee.

Do you provide after-sales service?

Yes, after you place an order, we will have a dedicated account manager online 24 hours to solve some problems you may have in use.

JIMI STEEL MILL LIMITED

JIMI STEEL MILL LIMITED