Product details

1052 aluminum rod is a kind of aluminum rod material.

1052 aluminum rod belongs to 1000 series aluminum alloy, which is aluminum magnesium alloy. 1052 aluminum rod strength, corrosion resistance, good welding performance, can be manufactured ocean ships and ship parts, aircraft fuel tanks, oil and gas pipes, vehicle aluminum, structural parts, containers, etc.

|

Surface Treatment:

|

Polished

|

|

Technique:

|

Cold Drawn

|

|

Hardness:

|

standard

|

|

Al (Min):

|

99%

|

|

Material:

|

Aluminun

|

|

Temper:

|

T3 - T8

|

|

Tolerance:

|

±1%

|

|

Sample:

|

Avaliable

|

|

Application:

|

construction

|

|

Shape:

|

Round

|

|

Yield (≥ MPa):

|

90

|

|

Ultimate Strength (≥ MPa):

|

30

|

|

Processing Service:

|

Cutting

|

|

Surface:

|

Polished

|

|

Length:

|

1m-6m

|

|

Package:

|

Standard Seaworthy Package

|

|

Standard:

|

ASTM AISI JIS DIN GB

|

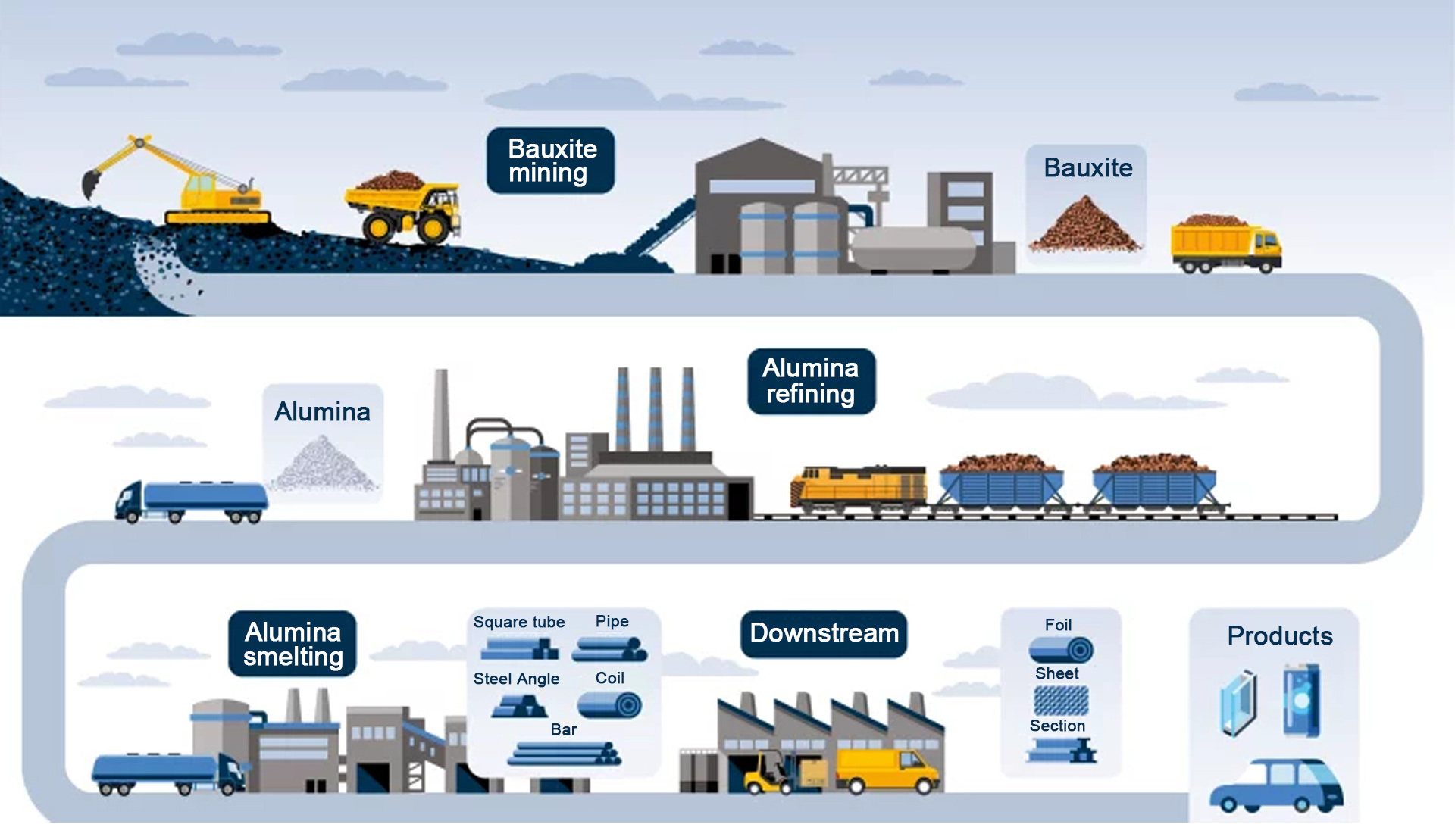

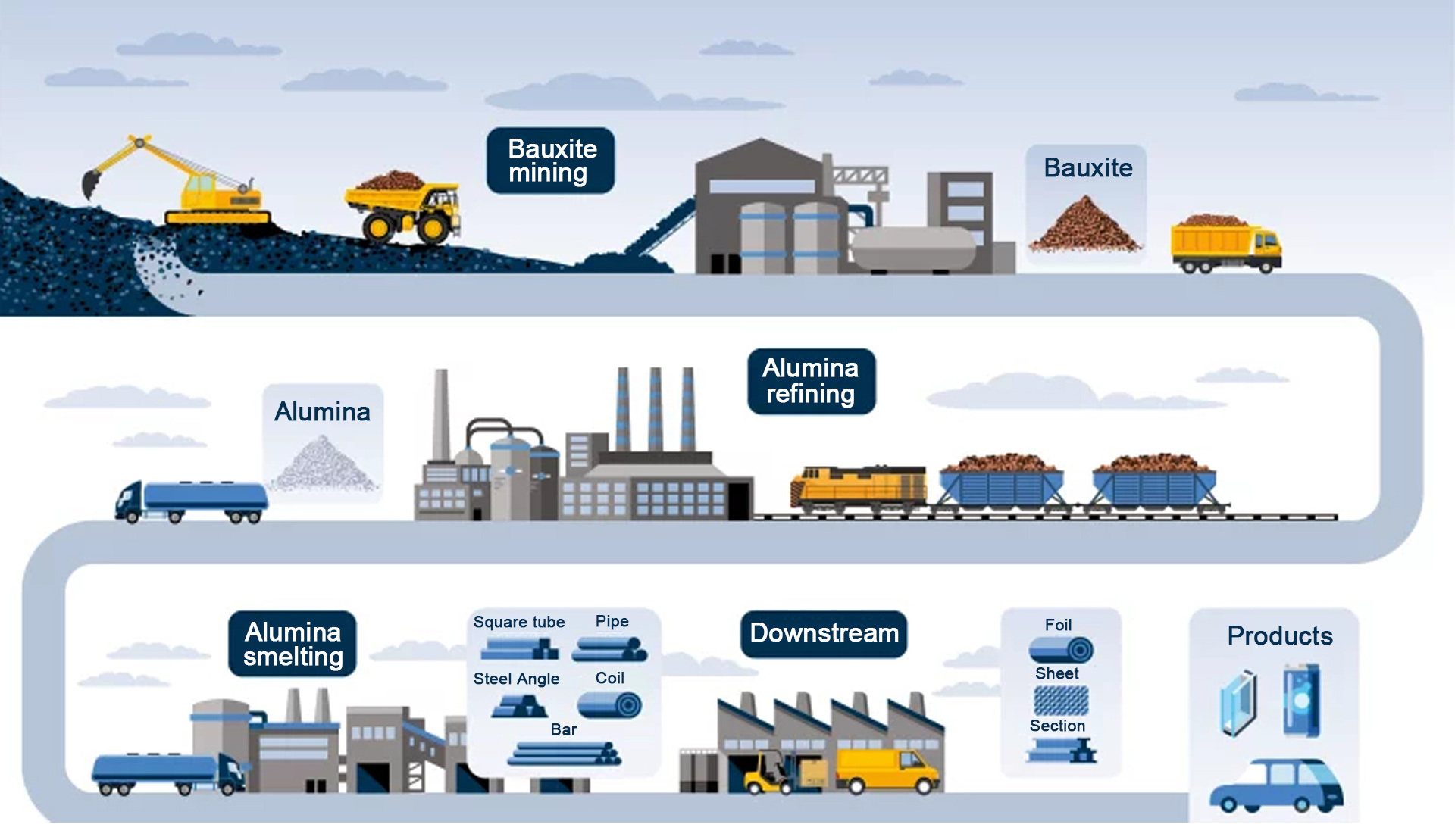

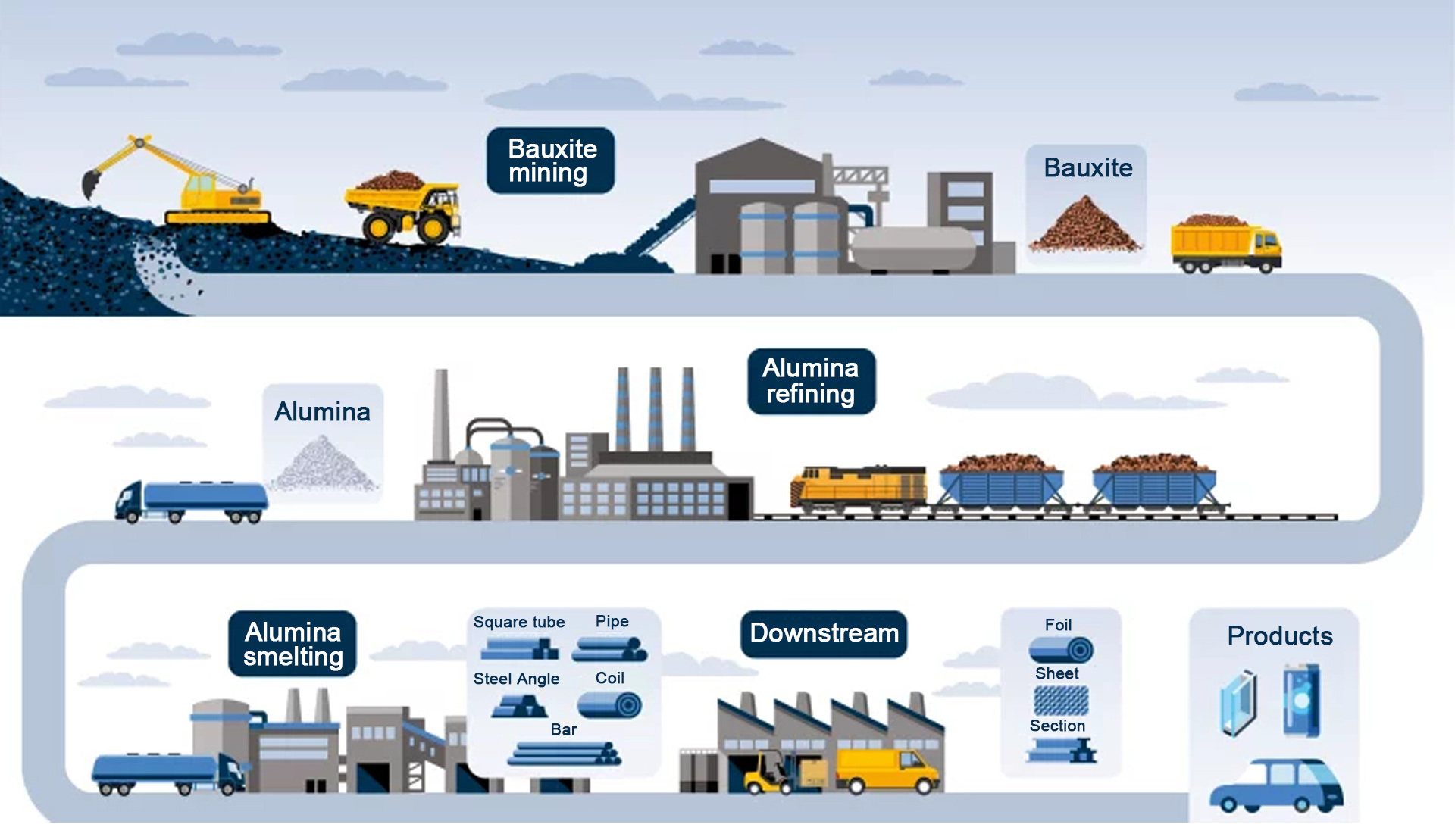

Product production process

We have advanced production lines and operating equipment, all products in the production of strict quality control to ensure that all products will not appear quality problems. All our products can also accept the professional quality inspection of third-party testing institutions and can issue relevant quality certificates.

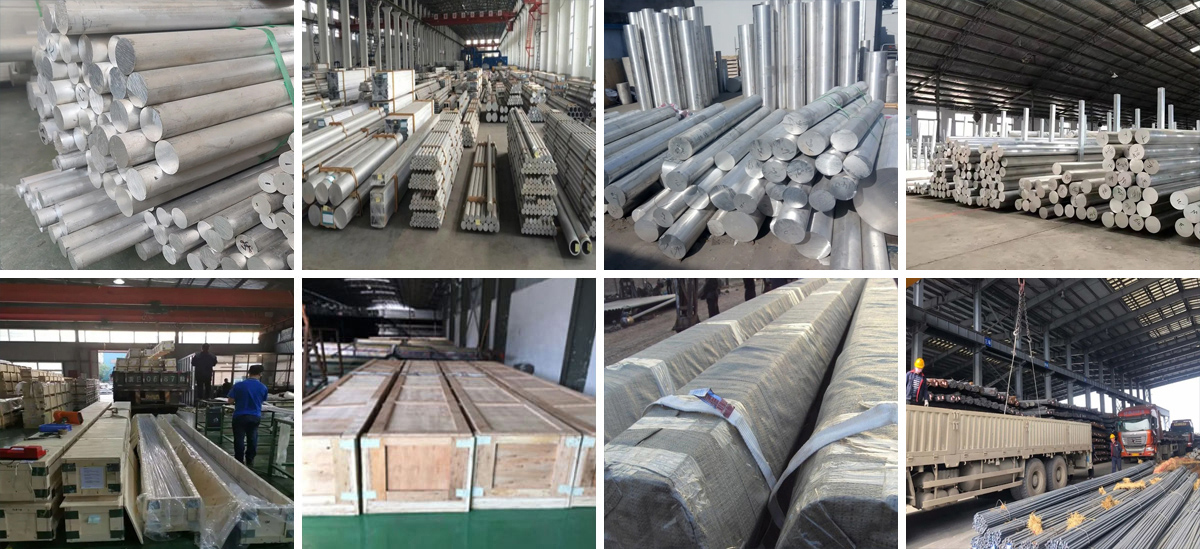

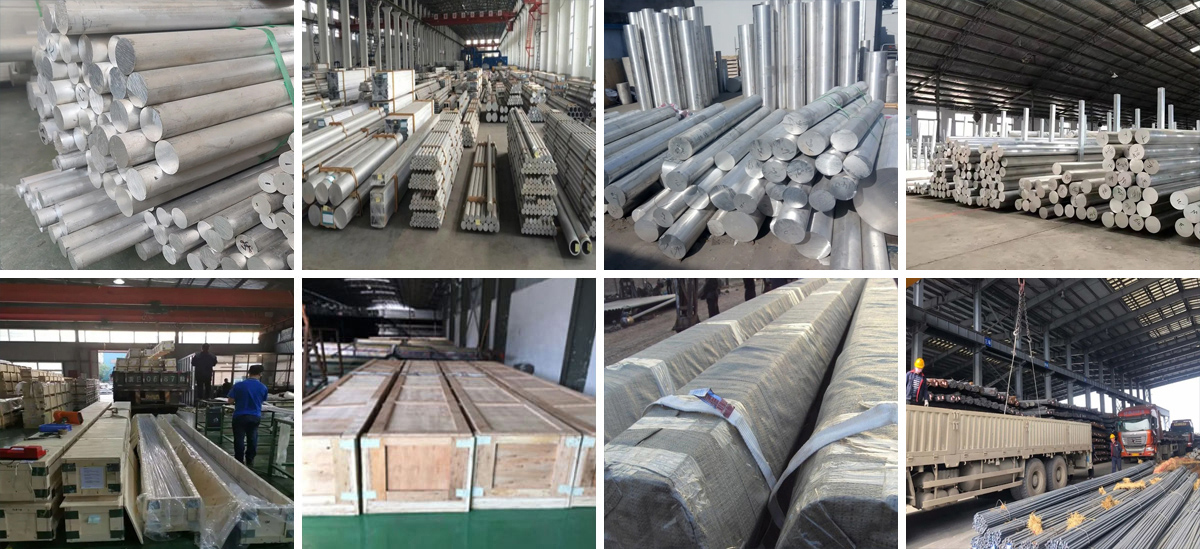

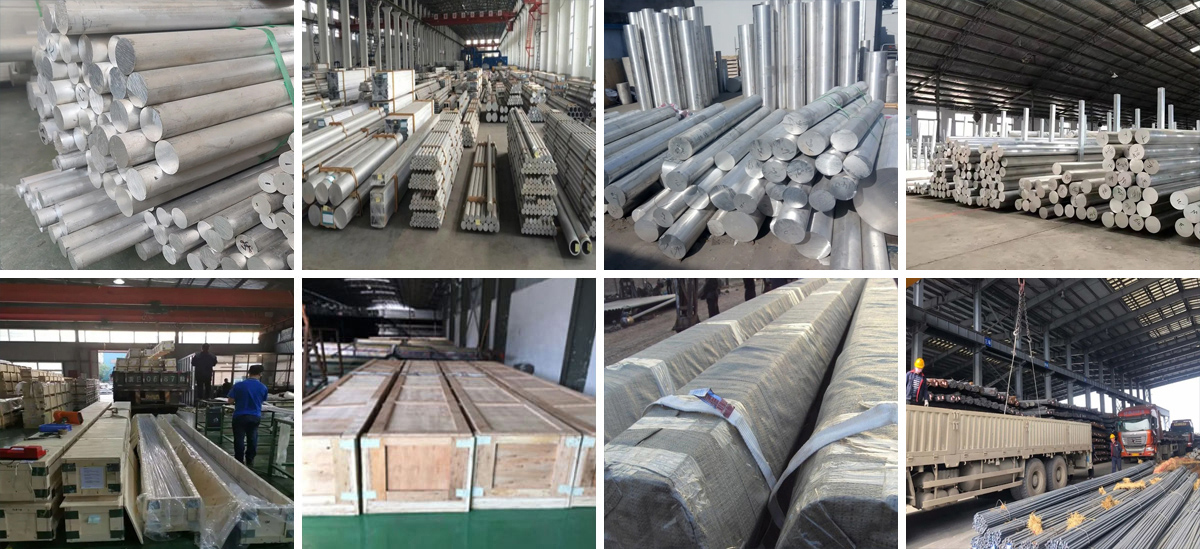

Product packaging and transportation

Customers can default to our packaging method can also be specified, we can give you professional advice according to your location to choose the appropriate packaging and transportation method, of course, you can also specify.

An aluminium alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Alloys composed mostly of aluminium have been very important in aerospace manufacturing since the introduction of metal-skinned aircraft. Aluminium–magnesium alloys are both lighter than other aluminium alloys and much less flammable than other alloys that contain a very high percentage of magnesium.

Aluminium alloy surfaces will develop a white, protective layer of aluminium oxide if left unprotected by anodizing and/or correct painting procedures. In a wet environment, galvanic corrosion can occur when an aluminium alloy is placed in electrical contact with other metals with more positive corrosion potentials than aluminium, and an electrolyte is present that allows ion exchange. Also referred to as dissimilar-metal corrosion, this process can occur as exfoliation or as intergranular corrosion. Aluminium alloys can be improperly heat treated, causing internal element separation which corrodes the metal from the inside out.

Aluminium alloy compositions are registered with The Aluminum Association. Many organizations publish more specific standards for the manufacture of aluminium alloy, including the Society of Automotive Engineers standards organization, specifically its aerospace standards subgroups, and ASTM International.

|

Alloy

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

V

|

Ti

|

Bi

|

Ga

|

Pb

|

Zr

|

Limits††

|

Al

|

|

Each

|

Total

|

|

1050[47]

|

0.25

|

0.4

|

0.05

|

0.05

|

0.05

|

|

|

0.05

|

|

|

|

|

|

0.03

|

|

99.5 min

|

|

1060

|

0.25

|

0.35

|

0.05

|

0.028

|

0.03

|

0.03

|

0.05

|

0.05

|

0.028

|

0.03

|

0.03

|

0.03

|

0.03

|

0.028

|

|

99.6 min

|

|

1100

|

0.95 Si+Fe

|

0.05–0.20

|

0.05

|

|

|

0.1

|

|

|

|

|

|

|

0.05

|

0.15

|

99.0 min

|

|

1199[47]

|

0.006

|

0.006

|

0.006

|

0.002

|

0.006

|

|

0.006

|

0.005

|

0.002

|

|

0.005

|

|

|

0.002

|

|

99.99 min

|

|

2014

|

0.50–1.2

|

0.7

|

3.9–5.0

|

0.40–1.2

|

0.20–0.8

|

0.1

|

0.25

|

|

0.15

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

2024

|

0.5

|

0.5

|

3.8–4.9

|

0.30–0.9

|

1.2–1.8

|

0.1

|

0.25

|

|

0.15

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

2219

|

0.2

|

0.3

|

5.8–6.8

|

0.20–0.40

|

0.02

|

|

0.1

|

0.05–0.15

|

0.02–0.10

|

|

|

|

0.10–0.25

|

0.05

|

0.15

|

remainder

|

|

3003

|

0.6

|

0.7

|

0.05–0.20

|

1.0–1.5

|

|

|

0.1

|

|

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

3004

|

0.3

|

0.7

|

0.25

|

1.0–1.5

|

0.8–1.3

|

|

0.25

|

|

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

3102

|

0.4

|

0.7

|

0.1

|

0.05–0.40

|

|

|

0.3

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

4043

|

4.5–6.0

|

0.8

|

0.3

|

0.05

|

0.05

|

|

0.1

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5005

|

0.3

|

0.7

|

0.2

|

0.2

|

0.5–1.1

|

0.1

|

0.25

|

|

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5052

|

0.25

|

0.4

|

0.1

|

0.1

|

2.2–2.8

|

0.15–0.35

|

0.1

|

|

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5083

|

0.4

|

0.4

|

0.1

|

0.40–1.0

|

4.0–4.9

|

0.05–0.25

|

0.25

|

|

0.15

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5086

|

0.4

|

0.5

|

0.1

|

0.20–0.7

|

3.5–4.5

|

0.05–0.25

|

0.25

|

|

0.15

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5154

|

0.25

|

0.4

|

0.1

|

0.1

|

3.10–3.90

|

0.15–0.35

|

0.2

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5356

|

0.25

|

0.4

|

0.1

|

0.1

|

4.50–5.50

|

0.05–0.20

|

0.1

|

|

0.06–0.20

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5454

|

0.25

|

0.4

|

0.1

|

0.50–1.0

|

2.4–3.0

|

0.05–0.20

|

0.25

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5456

|

0.25

|

0.4

|

0.1

|

0.50–1.0

|

4.7–5.5

|

0.05–0.20

|

0.25

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

5754

|

0.4

|

0.4

|

0.1

|

0.5

|

2.6–3.6

|

0.3

|

0.2

|

|

0.15

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6005

|

0.6–0.9

|

0.35

|

0.1

|

0.1

|

0.40–0.6

|

0.1

|

0.1

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6005A†

|

0.50–0.9

|

0.35

|

0.3

|

0.5

|

0.40–0.7

|

0.3

|

0.2

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6060

|

0.30–0.6

|

0.10–0.30

|

0.1

|

0.1

|

0.35–0.6

|

0.05

|

0.15

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6061

|

0.40–0.8

|

0.7

|

0.15–0.40

|

0.15

|

0.8–1.2

|

0.04–0.35

|

0.25

|

|

0.15

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6063

|

0.20–0.6

|

0.35

|

0.1

|

0.1

|

0.45–0.9

|

0.1

|

0.1

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6066

|

0.9–1.8

|

0.5

|

0.7–1.2

|

0.6–1.1

|

0.8–1.4

|

0.4

|

0.25

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6070

|

1.0–1.7

|

0.5

|

0.15–0.40

|

0.40–1.0

|

0.50–1.2

|

0.1

|

0.25

|

|

0.15

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6082

|

0.7–1.3

|

0.5

|

0.1

|

0.40–1.0

|

0.60–1.2

|

0.25

|

0.2

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6105

|

0.6–1.0

|

0.35

|

0.1

|

0.1

|

0.45–0.8

|

0.1

|

0.1

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6162

|

0.40–0.8

|

0.5

|

0.2

|

0.1

|

0.7–1.1

|

0.1

|

0.25

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6262

|

0.40–0.8

|

0.7

|

0.15–0.40

|

0.15

|

0.8–1.2

|

0.04–0.14

|

0.25

|

|

0.15

|

0.40–0.7

|

|

0.40–0.7

|

|

0.05

|

0.15

|

remainder

|

|

6351

|

0.7–1.3

|

0.5

|

0.1

|

0.40–0.8

|

0.40–0.8

|

|

0.2

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

6463

|

0.20–0.6

|

0.15

|

0.2

|

0.05

|

0.45–0.9

|

|

0.05

|

|

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

7005

|

0.35

|

0.4

|

0.1

|

0.20–0.70

|

1.0–1.8

|

0.06–0.20

|

4.0–5.0

|

|

0.01–0.06

|

|

|

|

0.08–0.20

|

0.05

|

0.15

|

remainder

|

|

7022

|

0.5

|

0.5

|

0.50–1.00

|

0.10–0.40

|

2.60–3.70

|

0.10–0.30

|

4.30–5.20

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

7068

|

0.12

|

0.15

|

1.60–2.40

|

0.1

|

2.20–3.00

|

0.05

|

7.30–8.30

|

|

0.01

|

|

|

|

0.05–0.15

|

0.05

|

0.15

|

remainder

|

|

7072

|

0.7 Si+Fe

|

0.1

|

0.1

|

0.1

|

|

0.8–1.3

|

|

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

7075

|

0.4

|

0.5

|

1.2–2.0

|

0.3

|

2.1–2.9

|

0.18–0.28

|

5.1–6.1

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

7079

|

0.3

|

0.4

|

0.40–0.80

|

0.10–0.30

|

2.9–3.7

|

0.10–0.25

|

3.8–4.8

|

|

0.1

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

7116

|

0.15

|

0.3

|

0.50–1.1

|

0.05

|

0.8–1.4

|

|

4.2–5.2

|

0.05

|

0.05

|

|

0.03

|

|

|

0.05

|

0.15

|

remainder

|

|

7129

|

0.15

|

0.3

|

0.50–0.9

|

0.1

|

1.3–2.0

|

0.1

|

4.2–5.2

|

0.05

|

0.05

|

|

0.03

|

|

|

0.05

|

0.15

|

remainder

|

|

7178

|

0.4

|

0.5

|

1.6–2.4

|

0.3

|

2.4–3.1

|

0.18–0.28

|

6.3–7.3

|

|

0.2

|

|

|

|

|

0.05

|

0.15

|

remainder

|

|

8176[46]

|

0.03–0.15

|

0.40–1.0

|

|

|

|

|

0.1

|

|

|

|

0.03

|

|

|

0.05

|

0.15

|

remainder

|

|

Alloy

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

V

|

Ti

|

Bi

|

Ga

|

Pb

|

Zr

|

Limits††

|

Al

|

|

Each

|

Total

|

|

†Manganese plus chromium must be between 0.12 and 0.50%.

|

|

††This limit applies to all elements for which no other limit is specified on a given row, because no column exists or because the column is blank.

|

JIMI STEEL MILL CO.,LTD, (“JIMI Steel” for short) is an international company integrating production, processing and sales. Always stand from the customer's perspective and provide customers with one-stop steel procurement services.

Headquartered in Dezhou the company has successively invested and built production lines of galvanized steel, color coating steel, seamless steel pipe, cold-rolled sheet and stainless steel products in China; Meanwhile, it has established long-term and friendly relations with Baosteel, Tisco, Posco and other major domestic and international steel mills to conveniently and efficiently provide customers with high-quality products and services. In addition, the company has also set up its own warehouses in major domestic ports to ensure that the goods are delivered to customers at the first time.

As long as you need steel, JIMI Steel will give you the best support!

Manufacturing capacity

Our production line is running well, the product stock is sufficient, and we also maintain close cooperation with major domestic and foreign steel mills to ensure timely delivery of goods for customers

Logistics tracking

After receiving the order, we will quickly prepare the goods for you and send them out, and track the logistics throughout the process to ensure that the goods are safely and quickly delivered to the customer's designated location

Quality assurance

All our products are produced with high-quality raw materials, and all products can accept professional quality inspection by third-party testing institutions and can issue relevant quality certificates

Worry free after sale

After placing the order, we will have a special after-sales manager to docking you, to help you solve any problems that may occur in the use of the process, if necessary, we can assist you to return or exchange goods

Name: Jimmy

Tel: +86-15753107623

E-mail: admin@jimi-steel.com

WeChat: 008615753107623

Whatsapp: 008615753107623

Add: No.19 West Street, Guangtai Mall, Xinhu Street, Decheng District, Dezhou City, China

Frequently Asked Questions(FAQ)

Have you encountered any problems? Here are some of our most frequently asked questions and answers. If there is nothing you would like to see, please contact us

How do I order your steel?

To order our steel, you need to visit our website and then contact our sales team to provide you with the material, model, payment method and terms you want.

How long after the order?

Under normal circumstances, if we have it in stock, we will start delivery within 7-14 days. In other cases that need to be customized, we will communicate with you specifically about the time limit. After the production is completed, we will deliver the car to you according to the mode of transportation you choose.

Do you offer custom products?

Yes, we offer custom service. Can be based on your needs and conditions.

Do you offer a return service if I need to return a product?

Yes, if you need to return a product, we offer a return service. Please note that returns are subject to our return policy, please consult your contact's dedicated account manager for details.

How about the quality of your products? Is there a guarantee?

All our products are subject to strict quality testing and come with a quality guarantee.

Do you provide after-sales service?

Yes, after you place an order, we will have a dedicated account manager online 24 hours to solve some problems you may have in use.

JIMI STEEL MILL LIMITED

JIMI STEEL MILL LIMITED